StirLin-4 Liquid Nitrogen Generator with Atlas Copco PSA and air compressor - Parker Hannafin chiller and Chart HS-3000 not shown

DCT of shovel teeth castings on 4/18/2023

Metalex employees Ramiro Galvan, Debra James, Chris James, Jerry Bradway and Jeff Bacon

OFFICIAL USPTO NOTICE OF REGISTRATION

U.S. Application Serial No. 90718168

Mark: ETCSA CERTIFIED DCT

Owner: Emerging Technologies Certification and Standards Agency Incorporation

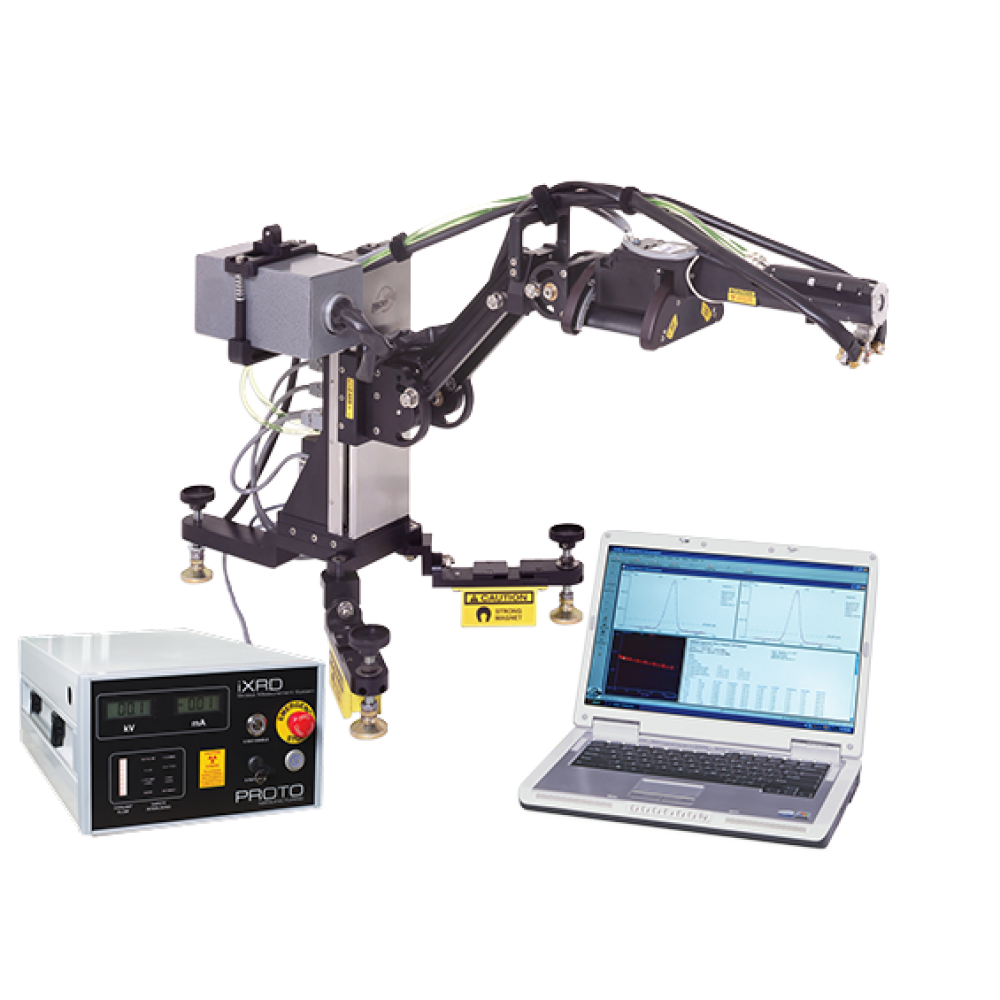

Measuring Residual Stress on 52100 bearing steel using X ray diffraction

Infinitely Renewable, Infinitely Recyclable™

On 1/7/2022, this trademark was registered with the Canadian Registrar of Trademarks and assigned # 2158963.

Linda Williams, DCI VP, on-site during tests

The 36K - largest DCT chamber in the world and proudly ‘Made in Canada’!

The 36K in action!

DEEP CRYOGENIC TREATMENT OF TITANIUM-BASED ALLOYS

T. Street, Z. Russell, D. Griffin, and K.P. Plucknett* Dalhousie University 1360 Barrington Street, Halifax, Nova Scotia, Canada, B3H 4R2 (*Corresponding author: kevin.plucknett@dal.ca)

J. Cahn Deep Cryogenics International Lunenburg, Nova Scotia

Jack and Linda in Waterton Provincial Park

Thorsten and Dave at Induspec Engineering

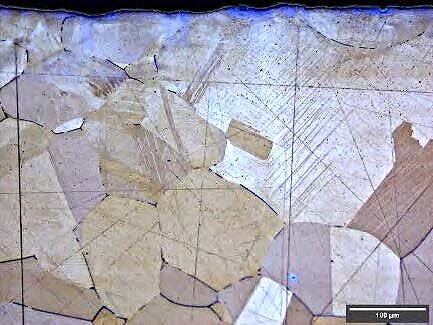

Electron Backscatter Diffraction (EBSD)

Grain distortion caused by TWIP in DC-treated Mn - after 2,000 lbs of abrasive rock crush during an ASTM G81 test at DCI

DCI’s CP-200vi and CP-1200 vi deep cryogenic processors.

DCT Gray Cast Iron without MnS Inclusions

Field testing DC-treated cone crusher liner material at DCI for a gold mine customer

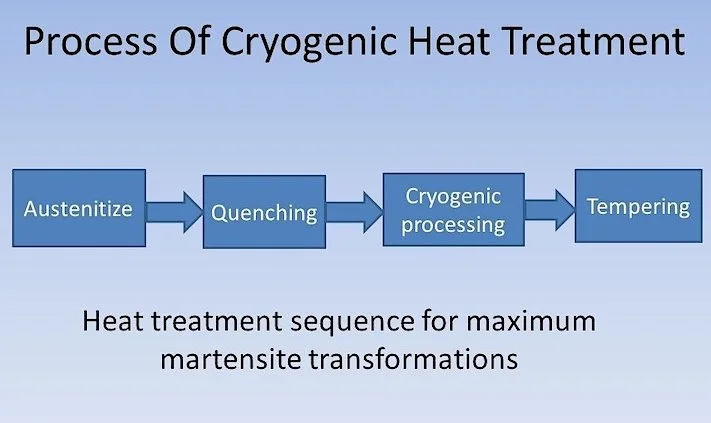

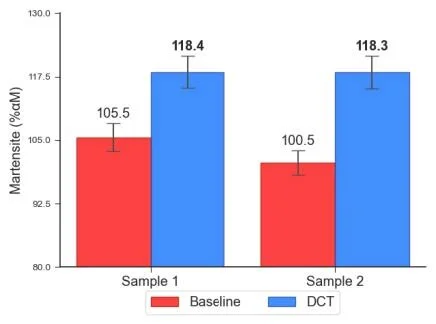

Martensite improvement after DCT

Hardness increase in chrome moly SAG Mill balls after deep cryogenic treatment.

Deep Cryogenics International will help the mining industry lower operating costs, increase net profit margin, reduce environmental impact and increase the safety of mining personnel.

3D surface analysis of DC treated copper with DCI’s Scanning White Light Interferometer

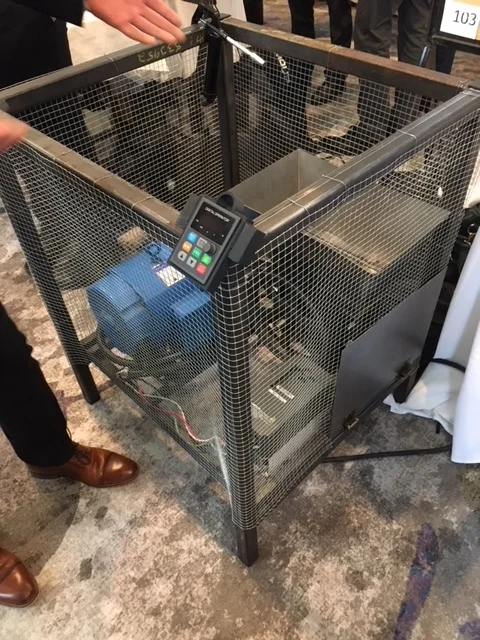

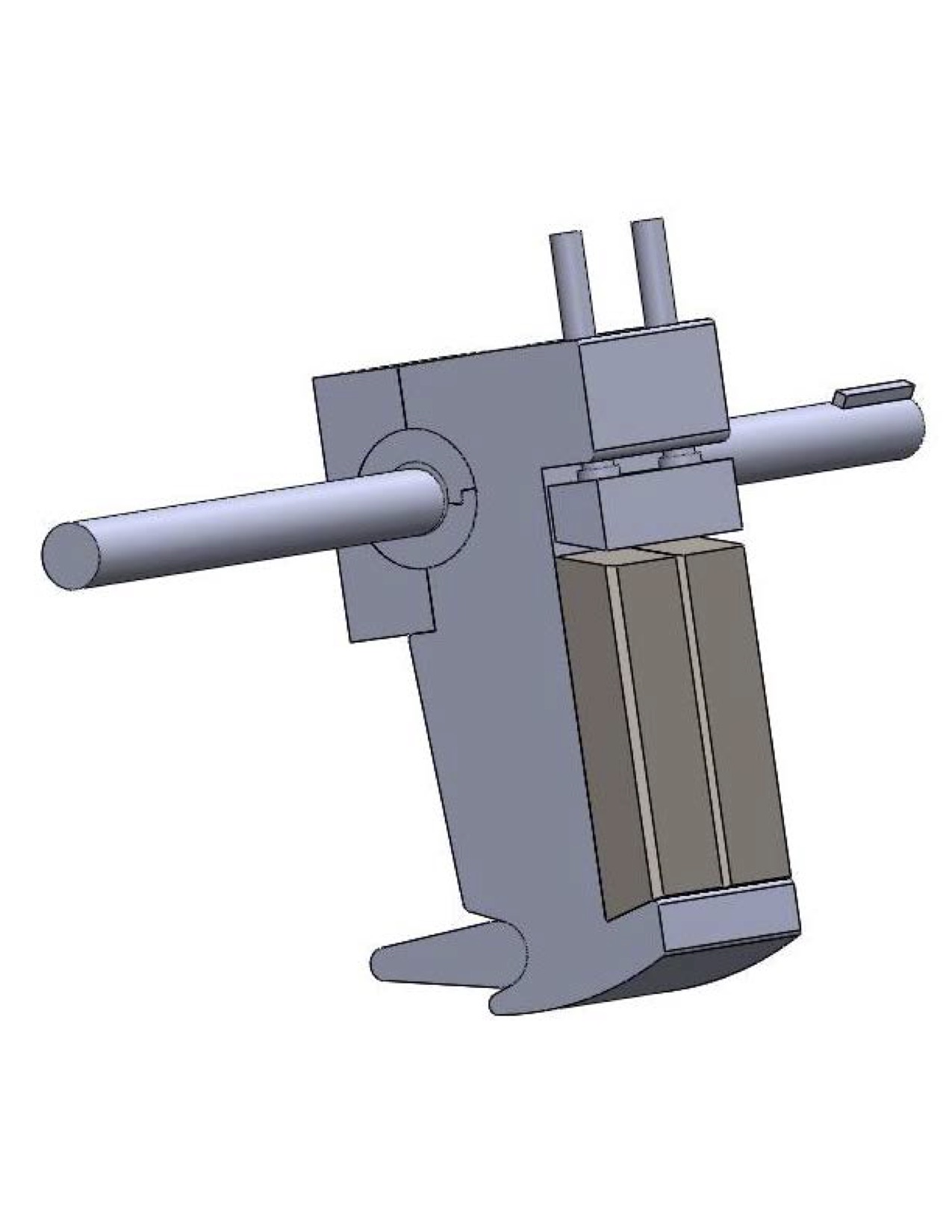

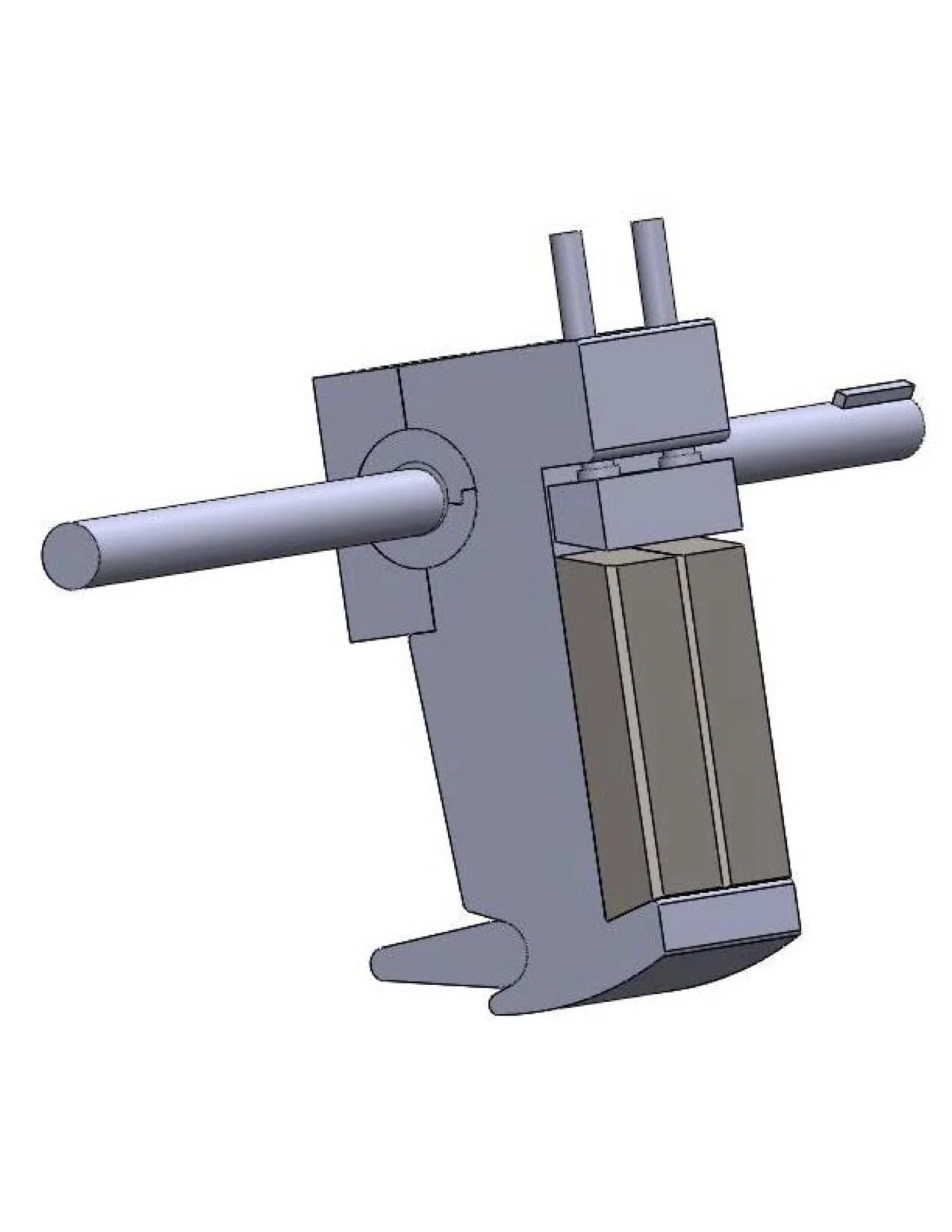

G81-97a Gouging Abrasion Wear Tester

ASTM G81-97a: Moving Jaw Assembly Gouging Abrasion Tester for Mining

ASTM G81-97a: Moving Jaw Assembly Gouging Abrasion Tester for Mining

nov 14,2023: loading big parts for dct

manganese steel feeder pans

It can be a challenge to manipulate 7,000 lbs of parts that are 15 feet long into our DCT chamber. DCI VP Linda Williams is the expert when it comes to safe and efficient material handling!

SEP 10, 2023: NEW DCI EQUIPMENT BROCHURE

for mining, energy and industry

We now offer the only industrial-size DCT chamber and liquid nitrogen generator platform in the world - dedicated to increasing the wear life of abrasive mining, O&G and construction items by 30%. Built for remote operation in challenging environments, this equipment can be purchased or leased from DCI.

may 3, 2023: dct cone crusher project

looking for a mining partner

DCI recently won a grant award by the Nova Scotia Mineral Resources Development Fund (MRDF) to optimize the wear benefit offered by deep cryogenics on 18-22% manganese cone crusher mantles and liners. Prior field trials at Eastern Canada gold mines provided up to a 24% wear life improvement on OEM-supplied and foreign-sourced castings.

DCI is seeking suppliers of cone crusher castings, as well as mining companies, interested in collaborating on field trials. DCI will fund a significant portion of the DCT and R&D test work. The results will be posted in industry mining magazines and speak to DCT reducing environmental impact, lowering risk to miners and increasing operational uptime.

To participate in this project contact Jack at 902-329-5466 or jack@deepcryogenics.com

april 20, 2023: tech Talk

how to interpret a dct readout

DCI uses a programmable logic controller (PLC) to generate the time and temperature formulas on all our DCT chambers. We also include a separate chart recorder that displays both current and historical records of what is happening inside the chamber.

During the ramp-down phase of a DCT cycle, liquid nitrogen (LN2) enters via copper serpentines and turns into a gas just above -320°F (-196°C). At higher temp’s, the latent heat in the payload quickly exchanges with the cold. But when the program arrives at lower temperatures, both the calibrated air thermocouple and part thermocouple often reflect real-time temperatures that lag behind (or in this case) overshoot the program set point. This is normal. The chamber and mat’l temp will soon align with the set point - once the payload temp stabilizes the payload mass undergoing DCT.

march 14, 2023: heat treater expands dct

more dct capacity in colorado

DCI has leased a second CP-200i DCT chamber to Metalex Thermal Specialties in Berthoud, CO. Two years ago, Metalex complemented their extensive heat treat capabilites by adding deep cryogenic treatment. With their first machine running at over 90% capacity each week, they just added a second and moved into a new location. Contact Chris James for DCT and heat treat services at 970-532-3796.

feb 14, 2023: dci wins qualification award

alberta innovates supports dct

Deep Cryogenics International has been awarded funding by Alberta Innovates Clean Resources Clean Technology Group to qualify, test and validate the world’s first deep cryogenic treatment (DCT) equipment built for mining applications - scaled for industrial use and export - integrating an on-site liquid nitrogen generator to provide infinitely renewable and infinitely recyclable™ liquid nitrogen (LN2). This will create a turnkey, engineered and customer-validated platform solution that can be leased or sold to domestic and export markets. The success of this project will enable a low cost, highly effective wear improvement technology to locate at remote mining locations - significantly reducing the high cost of diesel fuel and re-supply logistics. Kinross Gold Corporation will provide industry guidance and advice to de-risk the pilot plant.

jan 18, 2023: DCT of cast cyclone pumps

cnrl will get 25% more wear life

DCT of high chrome, white iron pump cyclones will yield 20-30% increased wear life in slurry environments. DCT of this 16,000 pound lot will take 3 days to perform, will cost a fraction of the actual replacement/downtime expense and only uses infinitely renewable, infinitely recyclable™ liquid nitrogen.

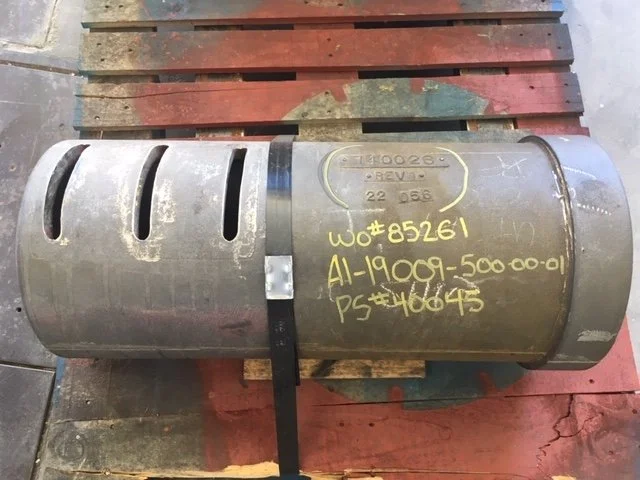

dec 26, 2022: DCT of shovel teeth & drills

dct adds 30% wear life to get’s

A international gold mine recently asked us to DCT shovel teeth, percussive mining drills and insertable carbide buttons.

Metallurgically, the results were an increase in delta martensite -correlating to an increase in field use wear life. No dimensional shift or modification to chemistry. Hardness only marginally improved since, unlike the hot side of thermal treatment, DCT improves wear life by a through-material precipitation of fine carbides, alignment of atomic lattice structure, a reduction in retained austenite and an increase in dislocations - improving both ultimate tensile strength and abrasive wear resistance.

nov 21, 2022: deep cryogenics in slovenia

institute of metals - ljubljana

Last week, we visited an outstanding lab and research center: the Institute of Metals in Ljubljana. We met with Dr. Bojan Podgornik and his staff, toured their facilities which included both advanced TEM and SEM, temp-variable UTS equipment, XRD and a very well-equipped microscopy preparation lab. We were generously hosted by Bojan and Barbara and we experienced the incredible beauty and warmth of Ljubljana. We see numerous opportunities to collaborate with the IMT and hope to generate a joint collaboration between the IMT, Turin Polytechnic and DCI to support both fundamental and applied research into the science of deep cryogenics.

nov 10, 2022: deep cryogenics in italy

dci at turin polytecnic

Today we visited old friends and fellow researchers at Polytechnico di Torino. Linda and I met with Cristiana Delprete, Eugenio Brusa, Carlo Rosso, Luigi Gianpio Di Maggio and Chiara Gastaldi (not in photo). We discussed research collaborations using DCT to improve manganese steel, bearings and gears with specialized testing performed in Turin. Grateful appreciation to the CanExport Innovation Program for providing support to our international business efforts. Let’s just say that the pasta, vino and gelato were beyond incredible!!!

sep 13, 2022: visitors at dci

nrc-irap and alberta SW

Last week, DCI welcomed Cal Koskowich and Nicole Daub from NRC-IRAP and Bev Thornton from Alberta SW to our facility. The toured the lab, were shown the liquid nitrogen generator and stepped inside the 36K DCT chamber before enjoying a great Mexican lunch in Twin Butte.

sep 6, 2022: INCREASE CASTING LIFE by 30%

DCT PUMP HOUSINGS AND CASTINGS

DCT will reduce retained austenite in high chrome white iron castings but the major improvement in wear is due to non-reversal carbide precipitation if DCT is performed below -240°F. Read more in the article below:

july 12, 2022: on-site liquid nitrogen plant

why buy? produce your own!

PRODUCE LIQUID NITROGEN ON-SITE: The control to our Liquid Nitrogen plant - simple, elegant and easy to use! Twin Helium compressors, a Sumitomo cold head, a 500 litre storage tank and up to 288 litres of liquid nitrogen produced per day. 99.0% purity. Made in Great Britain. Cost per litre is about 40 cents. If you want 1,000 litres a day - the larger plant produces LN2 at a cost of 20 cents a litre - half of what it costs to get it from Air Liquide, Praxair or Linde.

We will install, set up, train you to use it. We also lease our equipment at a fraction of the purchase price. Get rid of the high cost diesel delivery charges and produce LN2 on-site for your heat treat operation or manufacturing facility. Call us now!

july 7, 2022: new dct certification mark

uspto creates industry standard

The United States Patent and Trade Office has approved the first ever deep cryogenic treatment (DCT) certification mark - issued to the Emerging Technologies Certification and Standards Agency. The DCT Certification Mark uses X ray detection (XRD) to test, identify and validate the wear improvement resulting from DCT - in accordance with the well known ASTM E2860 Standard. XRD is a non-destructive test method.

XRD measures changes in atomic lattice spacing from residual and applied stress usually caused by casting, forging, machining and improper heat treatment. This stress often generates unseen defects or material strain that shorten item wear life. XRD has validated that DCT can improve both wear abrasive life and tensile strength.

june 28, 2022: DCI equipment passes review

The 36K passes lr design review

Deep Cryogenics International passes Design Approval by Lloyd's Register on their way to becoming the first and only manufacturer of deep cryogenic treatment equipment to be third party qualified and certified. LR Senior Surveyor Alex Dalmatov provides visual confirmation that DCI's largest chamber, the 36K, meets structural, process safety, piping and pressure system codes in conformance with CSA and CRN requirements.

june 14, 2022: Prairie technologies meet up

dimatec visits dci

Dimatec President Daryl Perry and Director of Market Growth Brian DeGagne visited DCI VP Linda Williams and Jack Cahn at their southern Alberta cabin over the weekend. So great to support fellow innovative businesses and just be in the presence of wonderful people. Dimatec is a leader in diamond drilling products for mining and energy companies. They have a fantastic company culture and it really shows.

may 17, 2022: deep cryogenics 101

deep cryogenics in hT magazine

Deep cryogenics was featured in the May issue of Heat Treat Today, a widely-read industry publication. See article below:

may 4, 2022: Jack Cahn interview

deep cryogenics in ‘the monty’

While preparing to DCT 14,000 lbs of cone crusher liners in the 36K, Jack Cahn and deep cryogenics were featured this month in an interview by Gord Montgomery of ‘the Monty’.

april 4, 2022: Current R&D at DCI

XRD to measure residual stress

DCI President Jack Cahn is adding to the deep cryogenics material database using DCI’s XRD (X ray diffraction) machine to test and measure residual stress in materials - both in baseline and post-DCT thermal condition. The 4 materials being measured are 52100 bearing steel, 13% manganese steel alloy, 4340 high carbon steel and 65-45-12 ductile cast iron.

This work is part of a Canadian Gov’t funded, ENGAGE grant study, authored by Cahn and Dr. Tonya Wolfe, jointly performed by Red Deer Polytechnic in Alberta and DCI. The study will correlate DCT material improvement using 3 destructive material tests (tensile strength ASTM E8, bend test for ductility ASTM E290 and pin-on-disc wear testing ASTM G99) with non-destructive measurement using XRD (residual strength ASTM 2860).

The challenge will be to build a scientific and repeatable correlation map between destructive and non-destructive testing of DC-treated materials that highlight observed mechanical improvement with changes in residual stress. For more information on residual stress measurement, see below

march 22, 2022: Deep cryo FOR KNIFE MAKERS

dci leases cp-200 to HEAT TREATER

Metalex Thermal Specialties in Berthoud, CO has expanded their HT capabilities by leasing a CP-200i from DCI. Within days after installing the 200, they began processing thousands of knife blanks to meet production demands. Metalex General Manager Chris James also intends to support local machine shops and injection mold makers with DCT - adding 30-70% increased wear life to D2, O1, H13, S7 and HSS tooling. You can reach Metalex at 970-532-3796 metalexts.com

february 15, 2022: A new dci patent filing

a deep cryogenic treatment chamber for industrial applications

On 2/14/2022, DCI filed a non-provisional utility patent for on-site production of liquid nitrogen using an LN2 generator, a large storage dewar for up to 10,000 litres of LN2 and a large DCT processor capable of economy-of-scale DCT processing for mining, road construction and remote work site applications.

January 19, 2022: A new dct trademark

deep cryogenic treatment is an environmentally green process

HOW DOES IT WORK? The DCT process uses nitrogen gas - obtained from air. A liquid nitrogen generator separates nitrogen gas (78% by volume) from oxygen (21%) and other trace gases - chilling the gas into a liquid. It is then used to improve wear, tensile strength and corrosion effect on metal objects by 20-70% in a cold thermal process. When the liquid nitrogen warms at -320°F, it returns to a gas - back into the air we breathe - leaving behind no chemicals, residue or pollutants but permanently improves the wear life of items we use every day.

DCT directly reduces the impact of greenhouse gas emissions by extending the life of items that require electricity, the burning of fossil fuels to manufacture and diesel to transport. It is a true ‘win-win’ for mining companies, heat treaters, manufacturers and anyone who cares about our environment.

december 7, 2021: bucket and shovel teeth

deep cryogenics improves wear life on bucket teeth by 30%

One of the world’s largest mining companies recently asked Induspec Engineering (North Bay, ON) to DCT bucket teeth in order to prove claims of increased wear life. Two different manufacturer-supplied products were deep cryogenically treated and the teeth were field tested at the mine site. Results were 34% wear life improvement on one manufacturer’s items and 31% wear life improvement on the other. See the actual results:

november 16, 2021: 36K - testeD and proven

dci builds largest dct chamber in the world - made in canada

DCI announces the successful testing of the 36K - the largest deep cryogenic treatment chamber in the world. After a 6 month, fast-paced build in Dartmouth, Nova Scotia, the prototype unit was both static and dynamically tested before live thermal cycling. With support by Linde, CTS, ACOA and NGEN, the 36K proved capable of thermal cycling between a low of -256°F and 300°F… a 556°F capability. Subsequent modifications should improve it for operation between -310°F - 350°F.

The 36K is patent-pending and undergoing full qualification by international standards agency Lloyd’s Register.

DCI will manufacture and lease new units to customers in the heat treat, power, mining and construction industries beginning Jan 2022.

october 26, 2021: NEW DEEP CRYO RESEARCH

NSERC ENGAGE GRANT

Alberta’s Red Deer College and DCI were awarded new research funding under an NSERC ENGAGE grant to explore deep cryogenic technology.

The RDC team, led by materials science PhD and Manager of the Centre for Innovation in Manufacturing, Dr. Tonya Wolfe, will collaborate with DCI on scientific research linking non-destructive testing (XRD) with standard destructive tests (tensile and pin-on-disc) to develop a correlation map for DCT material improvement. This research will help establish a better path to test, qualify and certify DC-treated items.

september 8, 2021: feature article in cmm

dct in canadian mining magazine

Deep Cryogenics International and the largest cryogenic treatment equipment in the world, the CP-36K, was featured in the latest edition of Canadian Mining Magazine. This equipment is the first and only cryogenic treatment equipment capable of treating full size mining, power, energy and road construction equipment.

At 8’ x 8’ x 20’ and with a 30,000 lb capacity, the CP-36K offers breakthrough wear life improvement and corrosion protection to large industrial items. DCI intends to lease the equipment to OEM’s, end users and heat treat facilities complete with support items, tailored R&D to optimize customer products and full certification by Lloyd’s Register. The CP-36K is available for lease beginning November 2021 and for ‘kick the tires’ trial usage beginning in October 2021.

august 24, 2021: Deep Cryogenics R&D paper

dct presentions at com 2021

Last week, Dr. Kevin Plucknett, Associate Dean of Research and Professor in the Dept. of Mechanical Engineering, presented the results of the 2020 ENGAGE Grant research between DCI and Dalhousie at the 60th Conference of Metallurgists (COM).

Sponsored by NSERC, the research explored the chemical and mechanical effect of DCT on two grades of titanium.

Summary: corrosion in DC-treated CP and 6Al-4V titanium was noticeably reduced while mechanical wear was unaffected.

Another DCT presentation at COM was “DCT as the Next Processing Step in Steel Industry” by Matic Jovicevic-Klug of the Institute of Metals and Technology.

july 27, 2021: DCI and Red deer polytechnic

dc applied research in alberta

Last week, DCI President Jack Cahn visited Dr. Tonya Wolfe, the Manager of RDC’s Centre for Innovation in Manufacturing. Besides 5 axis vertical and horizontal machining, CMM’s and laser cutting, CIM has a new ExOne binder jet capable of of 3D printing both ceramics and metal from powder.

RDC will collaborate this autumn with DCI on a new NSERC Engage grant, linking non-destructive testing (XRD) with standard destructive tests (tensile and pin-on-disc) to develop a correlation map for DCT material improvement. This information will increase the depth of material knowledge in DCI’s Material Improvement Computer Application (MICA) - a database that links DCT formulas to optimized end results.

july 20, 2021: new dci lab location

dci in southern alberta

We are growing! DCI now has another company lab location - southern Alberta. From the Maritimes to the prairies we want to support our Canadian customers with on-site testing that includes white light interferometry, optical microscopy, digital hardness testing, martensite measurement, X ray diffraction and more. Besides, it’s such a beautiful place to spend your time!

july 7, 2021: new dci test capability - xrd

residual stress in materials

DCI just ordered a Proto iXRD (X Ray Diffraction) test device for measuring the positive changes to residual stress and retained austenite caused by deep cryogenic treatment. This equipment will provide both field and lab-based test data confirming the use of DCT to improve the wear characteristics of metal.

The existing test procedures (ASTM E2860 Residual Stress and ASTM E975-03 Retained Austenite) are approved for use by all industries and are the basis of the DCT Engineering Standards and the USPTO patent-pending DCT Certification Mark.

After 70 years of development, now there’s a way to certify DCT for mining, tooling, power, industrial and scientific applications.

june 8, 2021: induspec dct now in operation

COMMERCIAL deep cryo IN CANADA

In fewer than 30 days, Induspec has quickly become a leading deep cryogenic treatment provider in Canada. They performed DCT on hydraulic components for an Ontario manufacturer, 500 lbs of large white cast iron for a BC foundry and now 2,800 pounds of shovel teeth for an international mining company.

Thorsten Brost and Dave Smits are able to treat up to 5,000 lbs of items in a single DCT run such as shovel and bucket teeth, grizzly bars, brake rotors, fluid hydraulic and pump items. They orient toward the forestry, mining and road construction. They each bring 30 years of professional engineering, data driven results and a focus on cost-effective solutions to the DCT world.

may 25, 2021: new deep cryogenic provider

induspec Eng - north bay, ontario

Canada’s newest and largest DCT provider is located in the heart of Ontario’s mining community. Operating DCI’s CP-1200 deep cryogenic processor, Induspec Engineering will add DCT to their professional engineering services while supporting hard rock mines, forestry, transportation and casting foundries. Co-owners Thorsten Brost, P. Eng and Dave Smits, P. Eng both have decades of heavy industry manufacturing experience. How can they reduce downtime? By Making Things Last Longer®

Thorsten Brost 705-223-1679 thorsten.brost@induspec.ca Dave Smits 705-475-8280 dave.smits@induspec.ca

May 18, 2021: manganese steel R&D update

NSBI funded study - Dal and DCI

Under the direction of Assistant Dean of Research, Dr. Kevin Plucknett and Dr. Mark Amagadzie, Dalhousie University will utilize both SEM and EBSD to reveal changes to grain size, orientation and carbide distribution in DC-treated manganese steel.

Funded under a generous grant from Nova Scotia Business Inc. (NSBI), Dalhousie will also explore the desirable work hardening characteristics of austenitic manganese - often used in crusher cones and ground engagement tools. Known as TRIP (Transformation Induced Plasticity) and TWIP (Twinning induced Plasticity), DCI uses deep cryogenics to increase the work life of manganese steel used in high abrasive conditions.

Induspec Engineering, a new DCT production facility in North Bay, ON, will provide DCT on the test coupons.

may 11, 2021: Mining Magazine features dct

gbr interview with jack cahn

DCI President Jack Cahn is featured in Global Business Report’s latest issue. The interview can be found below. For more information: https://www.linkedin.com/company/gbreports/

may 4, 2021: dct mining application

bucket and shovel teeth

No matter if you are digging in granite, overburden or mixed sand, DCT will extend the wear life of your Cat, Hitachi or Komatsu shovel teeth by a minimum of 30%. Regardless whether the domestic or offshore castings are made from cast iron, Hardox, manganese steel or chrome moly - DCT will reduce changeovers, lower downtime and increase output.

april 27, 2021: featured test equipment

material analysis before dct

How do we know what time and temperature formula to use when a customer supplies us with their parts? Most steel ‘looks’ identical yet requires different heat treat and cryogenics recipes to improve the mechanical and wear characteristics.

We use our Oxford Vulcan LIBS Device (Laser Induced Breakdown Spectroscopy) - a chemical/physical tester that gives exact chemistry readings so that we DCT using the right formula for the right material. We are the only DCT company in the world that performs material analysis and confirms customer material before DCT.

april 20, 2021: DCT + HT = longer wear life

perform dct after heat treating

Don’t leave money on the table! After heat treating, use deep cryogenics to capture up to 40% additional wear life! Expect to pay 12% additional cost to add 40% more wear life.

The numbers add up…longer life, reduced cost.

If your heat treater doesn’t offer DCT, call us: 902-329-5466

april 13, 2021: reduce mro on pump parts

dct for slurry and paste pumps

If your operation uses Putzmeister, Schwing Bioset, GIW or Weir hydraulic pumps - we can increase the operational life of your seal plates, impellers, shafts and wear parts by almost 50% at a cost of about 10%. Our process works best on these 400 series stainless steel, grey/ductile/white cast iron and carbon steel items. If aggregate and sand slurry are driving up your backfill costs and Covid has impacted your labor - use deep cryogenic treatment.

NOW WITH A NEW LOCATION IN NORTH BAY, ON

April 7, 2021: new product-cryo processors

DCI NOW AN EXCLUSIVE DISTRIBUTOR

DCI is now the exclusive distributor in Canada of the only vacuum insulated deep cryogenic treatment processor in the world. Designed by MIT physics PhD Dr. Jeff Levine, the CP-series includes the CP-200vi, CP-500vi and CP-1200vi with volumetric treatment capacities of 7, 17 and 42 cubic feet and payload weight limits of 1,500, 2500 and 4,000 lbs.

With their upcoming release of the largest DCT processor in the world (8’ x 8’ x 20’; 30,000 pound capacity), DCI can supply a full range of cryogenic processing equipment to manufacturers, casting and heat treat facilities, tool and die shops and anyone wanting to extend the wear life of metal items.

march 23, 2021: DALHOUSIE/DCI RESEARCH

DCT OF TITANIUM-BASED ALLOYS

Dr. Kevin Plucknett, Associate Dean of Research and Professor in the Dept. of Mechanical Engineering, will present the results of the 2020 ENGAGE Grant research between DCI and Dalhousie at the 60th Conference of Metallurgists (COM) on August 17, 2021. The research was sponsored by NSERC and will cover the significant corrosion improvement to CP and 6Al-4V titanium generated in 10, 24 and 72 hour DCT protocols.

Another DCT presentation at COM will be “DCT as the Next Processing Step in Steel Industry” by Matic Jovicevic-Klug of the Institute of Metals and Technology.

march 16, 2021: dCT arrives in north bay

new deep cryo facility in ontario

A production DCT facility is opening in North Bay in April to support the mining, transportation and forestry industries. Now shovel and bucket teeth, gears, bearings, pump impellers and castings can gain 30-60% increase in wear life at 10% cost with local support and service. DCI has partnered with a North Bay engineering company to offer this service. More coming soon!

february 24, 2021: dci’s ln2 procedure

SAFE HANDLING OF LIQUID NITROGEN

Liquid nitrogen (LN2) is non-flammable and non-explosive. It comprises 78% of the air that we breathe. However, it must be treated with respect when used in an industrial setting. Here’s our procedure for safe handling of LN2.

february 16, 2021: new patent filing

DCT tank for industrial use

DCI President Jack Cahn filed a utility provisional patent for the scale-up deep cryogenic treatment tank he recently invented. USPTO 62/816,930 is now patent-pending and describes a tank sized for treating mining and road construction components such as manganese crusher cone mantles and liners, big slurry and paste pump impellers and large volumes of shovel and bucket teeth. The tank will be the largest in the world, produced in Canada and designed to extend the wear life of items by 20-60% using the green process of deep cryogenics.

december 16, 2020: new dci board member

dr. hani henein

DCI welcomes a well-known and respected professor in the Department of Chemicals & Materials Engineering at the University of Alberta since 1989, Hani teaches and performs research on pipeline steels, metal-matrix composites and rapid solidification. He now partners with industry in research and has extensive international collaborations.

december 2, 2020: new dci board member

dr. rob stephens

DCI welcomes the former Director of Applied Research and Technology at Teck and current President at Tech2Strat Consulting. Rob is focused on the nexus of technology development, innovation, and strategy. He is passionate about the need for innovation in the mining and materials sector, including sustainability challenges.

november 17, 2020: new dci board member

alistair ross

DCI welcomes the CEO of Rockcliff Metals, Alistair Ross, to the Advisory Board. The former Head of Mining and Milling for Vale’s North Atlantic Base Metals Operations, Alistair is widely regarded for his strategic vision, tactical insight and guidance in successful business execution.

october 20, 2020: DCI Featured on Webinar

mining over canada

Deep Cryogenic Technology was featured on the Canadian Securities Exchange program Tech Tuesdays. DCI President Jack Cahn was one of three innovators presenting new technologies.

october 14, 2020: Cast Iron R&D - Part 1

Microstructure analysis

DCI is performing research into three cast irons used in slurry and paste pumps, GET’s, housings, pumps, gears, shafts and sprockets. The materials are G2 gray, 65-45 ductile and 80-55. Part I looks at changes in microstructure, hardness and graphite morphology after deep cryogenic treatment (see below). Part II will include wear testing to simulate application in brake rotors, slurry pumps and ground engagement tools - coming Dec 2020.

october 6, 2020: the test lab at DCI

how we perform r&d

As the only DC research facility in the world, we focus our efforts on lab and field testing to increase wear life. We mostly explore the ‘D’ in R&D - Development so that our customers can use our process to increase operational uptime and lower the cost of wear items. Our lab process flow is shown below.

september 22, 2020: DCT CERTIFICATION MARK

new test & approval procedure

The Emerging Technologies Certification and Standards Agency has filed a certification mark and engineering standards with the US Patent Trade Office. DCI President Jack Cahn has established a test method that certifies DC - treated items.

This ASTM - recognized procedure uses X-ray diffraction to test and certify parts used in mining, energy, power, and transportation - industries that already rely on heat treatment. Deep cryogenic treatment increases material wear life by 20-70% following conventional heat treatment - simply by completing the thermal processing cycle.

july 28, 2020: dct improves sag mill media

hardness improved - longer life

Our deep cryogenic process converted softer retained austenite into harder martensite in commercially available mill balls. The resulting hardness improvement will increase the wear life of cast and forged media used in grinding operations for mining and road construction. Now, more than ever, use DCT to:

lower your fixed cost of operations,

reduce safety risk to workers

reduce environmental impact

increase net profitability,

july 13, 2020: DCT improves TRip steel

less wear on oil-quenched steel

We have discovered an improvement to Transformation-Induced Plasticity (TRIP) steel used in wear hardening environments such as crusher cones, mining bucket and truck liners, screens and feed chutes. Read our summary 1 pager below:

june 9, 2020: dct improves high wear Mn

innotech confirms dct changes

Alberta’s premier materials science lab has confirmed the reduction of harmful carbide precipitation at grain boundaries in 13% manganese steel following DCI’s deep cryogenic treatment. Etched micrographs at 800X and 1,000X revealed the changes.

DCI’s process extends the wear life of 13%, 18% and 21% cone crusher mantles and liners for mining and road construction. Call us at 902-329-5466 to increase your operational uptime!

may 19, 2020: DCI stays open during covid-19

dci supports canadian mines

We have remained open during COVID-19, supporting Canada's mining community. Deep Cryogenics is about #MakingThingsLastLonger - especially manganese cone crushers: mantles, liners and other abrasive wear parts. Extend operational uptime, reduce time and cost of replacement parts and get more out of what you already have! Check out the short article below, just published by the International Manganese Institute. Call Jack Cahn at DCI to try deep cryogenic treatment or a conduct a research study 902-329-5466

february 27, 2020: DCI Press

DCI QUOTE FOR MINING

DCI President Jack Cahn was recently quoted in the mining publication Global Business Reports. "While some innovations change or reinvent processes that have been in place for years, others enhance what is already in use… “Making items last longer is the eternal engineering challenge and this is what the Deep Cryogenics process does,” stated Jack Cahn, founder and president..."

february 20, 2020: NRC-IRAP funded study

dci improves crusher cone life

Canada's NRC-IRAP has funded Innotech Alberta and DCI to perform a collaborative study on deep cryogenic treatment of manganese steel. In a recent G81-97 gouging abrasion test, DCI proved that deep cryogenic treatment reduces material erosion on manganese steel used in abrasive rock crush of greenstone granite. The G81 test simulates the mining application use of manganese steel in crusher cones, mantles and liners.

The improvement offered by DCT is a significant step toward reducing environmental impact, lowering carbon footprint and reducing the risk of injury to miners, while also increasing uptime of critical equipment and reducing diesel consumption to resupply short-life wear parts.

february 4, 2020: The largest DC tank in canada

dci adds second deep cryo tank

Our new deep cryogenic tank is ready for production treatment of mining, tool & die, power and industrial items like bucket teeth, slurry pump liners, cone crusher mantles, hardened tooling, brake rotors, or marine bearings and gears. Using infinitely renewable and recyclable liquid nitrogen, the process is environmentally sound while extending the wear life of metal items.

We are also working on a scale-up DC tank to be located near the center of mining activity in Ontario.

january 22, 2020: more test lab equip

Dci grows r&d capabilities

Our latest test lab item: a high precision scale that resolves to .002" of a gram. We use it for measuring material loss on DC treated coupons following a G81 gouging abrasion test. The G81 tester straddles both lab and field testing as one of the only ways of measuring the effect of deep cryogenic improvement on bucket loader teeth, paste pump/slurry items, drag lines, track links and other abrasive wear items. We simulate the abrasive action of rock crushing using screened greenstone granite and then monitor the wear effect on both baseline and DC treated coupons. Final evaluation and analysis requires use of our 1,000x Olympus microscope, our Filmetrics scanning white light interferometer and the Fristaden weight scale (pictured to the left).

january 14, 2020: Canada-US Mining pact

good news for dci and Canada

CANADA and the US announced Thursday they have finalized the Canada-US Joint Action Plan on Critical Minerals Collaboration, aimed to advance the countries’ mutual interest in securing supply chains for the critical minerals needed for manufacturing sectors, communication technology, aerospace and defence, and clean technology.

Of the 35 minerals and metals the US deemed critical earlier this year, Canada was identified as a major import source for 13.

december 4, 2019:energy & mines in toronto

DCI ATTENDS WORLD CONGRESS

It wasn’t all presentations on decarbonizing material movement, small modular reactors and wind energy! Maarten Van Koppen, Energy and Sustainability Manager with Newmont Goldcorp joins DCI President Jack Cahn for a drink after a day of Cleantech discussions. The mining industry is embracing the use of renewable energy, an active reduction in greenhouse gasses and pursuit of better operating efficiency through environmental action. The industry is seeking real change, not just the optics.

november 25, 2019: mining steel R&D

dci supports canadian mining

We invest our time to improve the reliability of steel alloys used in abrasive environments such as paste pumps, rock drills, crusher cones and grinding media. This week we are performing 72-hour deep cryogenic treatment on 16 varieties of work-hardening manganese steel, high carbon and stainless, nickel, AR400 plate, aluminum, tool steel, ductile and grey cast iron. After DCT, we will test for wear, abrasion, hardness and perform full metallurgical analysis using a microscope and a scanning white light interferometers

november 5, 2019: new test equipment

metallurgical analysis

Our latest purchase is an Olympus BX53 Metallurgical Analysis Microscope. Capable of 1,000x resolution, we can detect reduced grain size, phase changes and reductions in porosity, occlusions and material defects that occur when metal is deep cryogenically treated.

october 28, 2019: r&D in action

deep cryogenics

DCI's metallography team, Ryley LeBlanc and Linda Williams, prepare samples of 110 copper and 4340 high carbon steel using our Pace twin-platen polishing station. Their end result will be a mirror finish using 1200-grit wet paper before diamond suspension in cloth. Nital staining will follow to enhance grain structure before examination under our Olympus 1000x microscope. We can detect changes in phase, grain size, particles, inclusions, porosity and more using our specialized analysis software. Our team is excited to continue building our capacity in test instrumentation, metallographic prep and image analysis.

october 21, 20129: mining conference

jack cahn presents dct

Deep Cryogenics President Jack Cahn presented our deep cryogenic technology at the Atlantic Canada Mineral Processors Conference on 10/16/19. The focus was on mining and how DCI's cold thermal technology can reduce wear and corrosion by 30-70% on slurry and paste pumps, mill liners, crusher cones, hauler brakes, bucket teeth and other abrasive wear items.

october 17, 2019: digital hardness tester

dci adds astm E-18 test capability

Deep Cryogenics International has added a digital Rockwell hardness tester, capable of A, B, C and E testing to its lab. Along with our Leeb and Ultrasonic hardness testers, we can perform lab and field measurements on coupon samples as well as on full-size items weighing upwards of 10,000 pounds.

september 30, 2019: abrasive saw

dci brings coupon wafering in-house

Deep Cryogenics International can now prepare metal test coupons at our facility. We recently added a 14" precision cut-off saw that uses abrasive blades to wafer metal stock. This allows us to create smooth and damage-free surfaces on scientific research and test metallographic coupons. We are stocking dozens of superalloys, specialized mining steels, nickel, cast irons and non-ferrous materials for deep cryogenic test and treatment.

september 25, 2019: new R&D capability

dci adds metallographic prep

We are building out our test lab with a DE3 diamond engraver and a Pace twin platen grinder polisher, both used in metallographic preparation. We can now permanently engrave all coupon and test samples. We will then polish these samples into mirror finish for surface analysis using our white light interferometer or for EBSD.

september 10, 2019: new dct feature article

dci in canadian mining magazine

DCI President Jack Cahn authored a feature article in one of Canada’s foremost mining magazines that outlines the use of deep cryogenics to reduce abrasive wear in mining operations by 30 - 70%.

august 1, 2019: DC Production capacity

DCI adds a second DC Tank

With the purchase of a second DC treatment tank, DCI will have both prototype and production capability. Combined with the only on-site deep cryogenic test lab and R&D facility in the world, DCI is putting Canada on the map as the home of both cold climate and cold thermal technology.

July 24, 2019: on-site test lab

the world’s only dc test lab

DCI now has a full-spectrum test lab for mechanical and electrical analysis of deep cryogenically treated items. Conductivity, thermal analysis, surface profilometry, laser spectroscopy, wear and ferrite testing - DCI has opened the only test facility in the world for deep cryogenic R&D and scientific research.

june 27, 2019: new engineer on staff

dci hires materials engineer

DCI welcomes our new Materials Engineer - Ryley Leblanc. A recent engineering graduate of Dalhousie University in Halifax, Ryley's background includes mechanical property testing, software development, manufacturing procedures and project management. Ryley was instrumental in creation of the only G81-97a Abrasion Wear Testing device in eastern Canada. A native of Yarmouth, NS, we are excited to be working with him!

may 2, 2019: dci business relocation

lunenburg, nova scotia

DCI is now located in the picturesque Nova Scotia seaside town of Lunenburg - a sailing community and UNESCO World Heritage Site with colorful Victorian-era homes, folk festivals and knockout beauty. Visit us here for scallops and lobster…as well as deep cryogenic treatment.

april 19, 2019: deep cryogenic treatment

we dc treat to improve wear

It's pretty cold in there! As the temperature in our deep cryogenic tank drops to -310º F, small carbides precipitate out of the matrix and permanently reduce metal wear and abrasion. Items like gears, bearings, turbine blades, drilling items and slurry pump liners can benefit from this fast, green, low cost and effective technology.

april 8, 2019: the test device is complete!

dci NOW testING metal abrasion

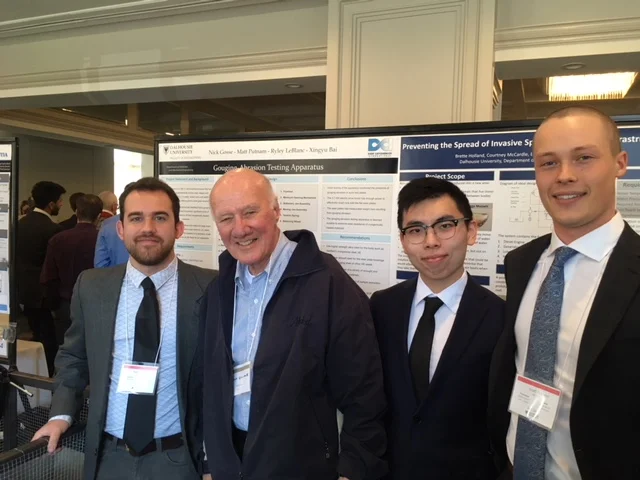

2019 Dalhousie ME project engineers Ryley Leblanc, Xingyu Bai and Matt Puttnam flank Class of ‘56 EE Chuck Williams at the presentation in Halifax.

march 19, 2019: Abrasion Tester ready 4/5/19

dalhousie project nears finish!

A custom built G81-97a Gouging Abrasion Wear Tester, specifically designed to test deep cryogenically treated material for mining applications, will be ready on 4/15/19.

Built for DCI by 4 senior engineering students (Matt Putnam, Ryley LeBlanc, Nick Gosse and Xingyu Bai) at Dalhousie University in Halifax as their Capstone Project, this tester will be fully functional for ASTM tests. DCI will add this testing capability to their existing equipment and will provide actual improvement data on DC-treated material that can be used in crusher teeth, conveyers, mill liners and gears.

march 12, 2019: new patent filing

a fixed location dct tank

DCI President Jack Cahn filed a USPTO patent for a large DCT tank - sited adjacent to rail or ocean shipping access. This tank is uniquely designed to accommodate large wind power gears, hydroelectric turbine segments and power generation shafts, blisks and hot section components.

march 11, 2019: nserc research funding

dci and dalhousie win R&D grant

The Natural Sciences and Engineering Research Council of Canada has awarded an Engage Grant to Dalhousie University and DCI to DC treat and test 3 high performance materials. This 6-month funded program will begin on May 1, 2019 and involve several researchers at Dal and Jack Cahn of DCI.

February 26, 2019: deep cryogenics at PDAC

DCI at canada’s BIG mining event

Jack Cahn and Linda Williams will attend the Prospectors and Developers Mining Conference in Toronto, March 3 - 6 to present deep cryogenic treatment to manufacturers and end users.

february 19, 2019: Deep cryo introduction

a quick 1 page summary

Here’s a snapshot of this step-change technology: how and why it works, what can be treated, cost and environmental benefits.

february 4, 2019: new patent filing

at last: DCt for power & ENERGY

DCI President Jack Cahn has filed the first and only USPTO patent for a scale-up deep cryogenic facility - dedicated to large size and large volume DCT of industrial items.

Titled: A Deep Cryogenic Treatment Facility for Industrial Applications, the patent describes on-site liquid nitrogen production, LN2 storage, the largest DC tank in the world, an authentication process for treated items and a test, validation and certification process that DCI patented in 2010 and was granted by the USPTO in 2017.

This patent breaks through the limitations of small commercial equipment and will help mining companies, O&G firms and public utilities to reduce wear on metal assets by 30-70%.

february 2, 2019: new dc MINING research

jack cahn and deep cryo R&D

JACK CAHN and DCI performed deep cryogenic treatment on several mining grade steels last week, both uncoated and with tungsten carbide overlay. Wear, hardness and tensile testing will be performed later this month in Alberta. Results of the study will be published in the fall edition of Canadian Mining Magazine.

Both Vecalloy and 4340 high carbon steel underwent DC treatment. No dimensional change occurs from DCT. Post-DCT annealing eliminates hydrogen embrittlement. Cahn anticipates a reduction in wear effect and an increase in yield strength.

january 15, 2019: Deep cryo MINING solution

nrcan comminution challenge

Jack Cahn proposed DCT as a solution to reduce energy use by 20% in the Natural Resources Canada Crush It Challenge. Comminution is the mining term that describes the crushing and grinding process to reduce ore size. His proposal is supported by Ausenco, the international engineering firm.

JANUARY 1, 2019: dci at coating workshop

amfi in edmonton alberta 2/12/19

Jack Cahn and DCI will attend the tungsten carbide/advanced overlay workshop hosted by InnoTech Alberta on Feb 12, 2019. Gary Fisher, PhD PEng, Team Lead of the Surface Engineering group will present applications, new technologies, opportunities and review industry use of hardfacing in oil, gas and mining.

december 17, 2018: DCT and Die sets

stamping dies and punch tooling

DCT adds 30-60% additional wear life to stamping, forming or draw dies at 10-20% of the orginal cost - whether D2, 440C, S-7 or A2.

december 8, 2018: DC tooling introduction

deep cryogenic treatment (DCT)

We are now treating machine tools, stamping dies, form tools and industrial tooling. Deep cryogenic treatment increases wear life at a fraction of the replacement cost.

december 3, 2018: Deep Cryo feature article

dc in industrial heating magazine

Jack Cahn authored a white paper on Deep Cryogenic Treatment for Marine and Oil and Gas Applications. Published in the Dec issue of Industrial Heating trade magazine, this feature article explores deep cryogenic challenges and solutions to industry-wide wear and corrosion. See article below:

November 28, 2018: alberta dct project

mining industry tests deep cryo

Innotech Alberta has approved a funded technology assessment of deep cryogenics for use in the mining industry. The Alberta-based test facility will provide independent evaluation, material testing and recommendations for implementation of DCT.

High wear mining applications include slurry pumps, liners, crusher teeth, impellers and hydraulics.

november 19, 2018: DCI Test Bed in-process

dalhousie G81 project update

The four Dalhousie University engineering students have finalized their design review and will start construction of DCI’s ASTM G81-97a tester in 1/2019. Completion will be 4/2019.

DCI’s test bed is the only one in the world designed for field testing of crushed rock and other mining material using DC treated cast-iron test coupons. The coupons can be made from ductile, white, austempered or chrome moly cast iron. Unlike preliminary lab or in-situ part testing, this test bed will allow mining equipment manufacturers to test the DC process in field conditions using materials specific to their operation.

october 17, 2018: 1 page DC introduction

DEEP CRYOGENICS SUMMARY

A quick, easy-to-understand read on the disruptive material improvement process.

september 28, 2018: major dc report

irap report on deep cryogenics

The most comprehensive summary report on Deep Cryogenics, funded by NRC IRAP, was just released. Authored by Dr. Kevin Plucknett, associate Dean of Research at Dalhousie University, the report confirms the wear and corrosion improvement of DC and summarizes the challenges and opportunities of DC across multiple industries.

September 24, 2018; dci at dalhousie

dCI promotes engineering DEPT

DCI has sponsored a Dalhousie Capstone project for 4 engineering students. They will build a gouging abrasion tester, conforming to ASTM G81, for test applications. Jack Cahn will be the industry liaison on this program.

august 16, 2018: DCI Wins vc award

energia ventures funds dci

Deep Cryogenics International was awarded $20,000 by Fredericton, NB, investment group Energia Ventures. One of only 6 firms chosen in North America, DCI President Jack Cahn will attend a 13 week on-site incubation in NB in preparation for future seed round funding.

July 6, 2018: DCI wins Technology funding

deep cryogenics awarded grant

Deep Cryogenics was awarded a $45,000 grant by Innovacorp -ACOA in Halifax, Nova Scotia. With Linda and Jack is Andy Fillmore, Member of Parliament and Hugh MacKay, Member of the Legislative Assembly of Nova Scotia.

June 20, 2018: DCI at Global Petroleum Show

DCI at GPS in Calgary, Alberta

Monterey Bay Geologist Rick Schuster and DCI President Jack Cahn (right) in Calgary, Alberta at the Global Petroleum Show.

June 18, 2018: DCI IN canada

deep cryogenics in Nova Scotia

We are now open in the Atlantic Maritimes: Our new phone number is (902) 329-5466. Our web address is still: www.deepcryogenics.com

May 4, 2018: dci capital acquisition

deep cryogenics buys new tank

DCI President Jack Cahn has purchased a new DC tank. With a 22"x 34" capacity to treat up to 1,500 lbs, this tank will be used for scientific R&D and small scale DC treatment of customer items.

DCI will begin construction of the world's largest DC tank in mid-2020. At 10' x 10' x 20' and holding up to 200,000 pounds, it will be 50X larger than existing equipment and the only machine capable of treating power generation, mining, industrial forgings and large marine components.

April 26, 2018: DCI talk at nrc workshop

deep cryogenics in canada

DCI President Jack Cahn will discuss DC treatment solutions to reduce wear and corrosion on mining assets at a workshop of the NRC Mining Materials Wear and Corrosion Consortium on June 6, 2018, in Drummondville, Quebec, Canada.

April 15, 2018: Cryogenic research articles

deep cryogenics international

Deep Cryogenic International links to the CSA Treatment Database https://www.cryogenictreatmentdatabase.org/ DCI President Jack Cahn contributes to DC materials research.

march 28, 2018: Canadian grant

DEEP CRYOGENICS & DALHOUSIE U

Deep Cryogenics International is collaborating with Dr. Kevin Plucknett at Dalhousie University in Halifax, Nova Scotia on an NRC-IRAP grant to roadmap deep cryogenics across Canada.

march 6, 2018: DCI Science advisor

deep cryogenics sme, lecturer

Dr. Rob Thornton, PE and Lecturer at University of Leicester, UK, has joined Deep Cryogenics International as a Science Advisor. Dr. Thornton is a Subject Matter Expert in deep cryogenics. https://www.linkedin.com/in/robthornton1/

February 28, 2018: DCI External Advisor

former top scientist at tenaris

Dr. Teresa Perez, former principal scientist at Tenaris and currently with TEP Consulting, has joined Deep Cryogenics International as an External Advisor. Dr. Perez is a world recognized SME in corrosion and metallurgy. https://www.linkedin.com/in/teresa-perez-b4418867/

February 26, 2018: DCI Science advisor

former chief scientist at shell

Dr. Sergio Kapusta, former chief scientist at Shell and current engineering professor at Rice University, has joined Deep Cryogenics International as Chief Materials Science Advisor. https://www.linkedin.com/in/sergio-kapusta-5aa31b16/

February 20, 2018: UK incubation

DCI Invited to pitch at ogtc

Deep Cryogenics International was selected to pitch at OGTC's Tech X accelerator in Aberdeen, Scotland on 3/7/18. The opportunity is for a UK incubation. https://theogtc.com/media-centre/news/2018/tech-start-ups-vying-to-be-a-techx-pioneer/

February 2, 2018: international Status

dci opens a Canadian office

Deep Cryogenics International is now an Extra-Provincial Canadian Corporation listed in the Nova Scotia Registry of Joint Companies. Our Registry ID is 3314475.

October 17, 2017: deep cryogenics Database

material application program

DCI has developed a material improvement computer application that links DC treatment protocols to measured levels of improvement in steel alloys.

September 21, 2017: DNV-GL and DCI

Process qualification

Deep Cryogenics International and DNV-GL are in discussion to process-qualify deep cryogenic treatment of low-carbon alloy steel for pipeline application.

September 6, 2017: Full Patent FILING

USPTO # 15/696,757

On 9/6/17, Jack Cahn filed a non-provisional patent for Deep Cryogenic Treatment of Blowout Preventer Items. DC will reduce the catastrophic failure of BOP internal components, bolts and fasteners by 30-70%.

August 1, 2017: Patent Issued

USPto # 9,721,258

On 8/1/17, the USPTO issued a full patent to Jack Cahn for a standards-based means to authenticate, test and certify deep cryogenic treatment on metal and metal-matrix items. https://patents.google.com/patent/US9721258B2/en?oq=+9%2c721%2c258

June 17, 2017: Full Patent FILING

USPTO # 15/626,102

On 6/17/17, Jack Cahn filed a non-provisional patent for Authentication, Testing and Certification of Additive Manufactured Items and Cryogenically Processed Additive Manufactured Items.

May 31, 2017: NEW Patent FILING

USPTO # 62/512,771

On 5/31/17, Jack Cahn filed a patent for Deep Cryogenic Treatment of Metal-Matrix Armor — the use of DC to reduce the physical impact effect on steel from blast, penetration or collision. Applications are industrial and military.

May 18, 2017: NEW Patent FILING

USPTO # 62/507,821

On 5/18/17, Jack Cahn filed a patent for a Large Format Deep Cryogenic Treatment Facility. The lack of scale-up equipment for industrial application has been a key limiting factor for widespread use of DC.

May 15, 2017: Scientific Article Posted

Deep Cryogenics Tech Briefing

DCI founder Jack Cahn gave this presentation at Draper Labs, Massachusetts Institute of Technology (MIT). The audience consisted of academics, material scientists and program managers. https://www.scribd.com/document/370873474/10-30-12-Deep-Cryogenics-International-Tech-Briefing